The causes for and solutions to India’s manufacturing angst may not lie in high land costs, excessively labour-friendly laws or excessive taxes, writes Ajit Balakrishnan.

Even if Mamata Banerjee, J Jayalalithaa, P Chidambaram, Nitish Kumar, Narendra Modi, our prime minister and officials in the Planning Commission cannot agree on many elements of public policy, there is one thing they speak for in one voice: the need to have more factories in India and to have existing factories grow at a faster rate.

The reason for this unusual consensus is not difficult to see. If you are a politician at any level and are campaigning at election time, what the sullen young men and women in front of you want to hear are your plans to get them industrial jobs. Such an opportunity will let them escape the dead-end jobs in their parents’ tiny farms - where some act of the weather gods can destroy in one instant the work of a whole season; where hours of back-breaking labour under the blazing sun do not yield enough rice or wheat or vegetables to feed their own families, let alone have anything left over to sell and earn some cash.

The reason for this unusual consensus is not difficult to see. If you are a politician at any level and are campaigning at election time, what the sullen young men and women in front of you want to hear are your plans to get them industrial jobs. Such an opportunity will let them escape the dead-end jobs in their parents’ tiny farms - where some act of the weather gods can destroy in one instant the work of a whole season; where hours of back-breaking labour under the blazing sun do not yield enough rice or wheat or vegetables to feed their own families, let alone have anything left over to sell and earn some cash.

Nor do they want equally dead-end jobs as fetchers and carriers in city shops far away from home. They yearn for a situation where their hard-won Class-VIII or Class-X pass certificates and willingness to slog are rewarded with jobs in which they are treated with respect and get paid enough to be able to afford a decent life, with a little left over to support ageing parents back on the farm.

But the same Mamata Banerjee, J Jayalalithaa, P Chidambaram, Nitish Kumar, Narendra Modi, our prime minister and officials in the Planning Commission also stare in unison at the stark reality of India’s manufacturing landscape: the vast majority of “factories” that exist in India are not the gleaming, well-lit, airy production units efficiently producing cars, mobile phones and refrigerators. Most are hole-in-the-wall operations, employing a mere dozen or so workers, and eking out a living dodging the excise and sales tax inspector.

This situation is not for lack of trying by our policy makers and political leaders. The most ambitious effort was made in 2005, when Special Economic Zones (SEZs) were legislated. Industrial units in these SEZs were offered land at throwaway prices and exempted from customs and excise duties and income tax. In some states, even the operation of labour laws was suspended. But to no avail. According to the government’s Economic Survey, the number of people employed in manufacturing in India actually dropped by four million in the past five years. This comes at a time when we ought to be creating several million manufacturing jobs every year, lest we drown in an immense national social crisis.

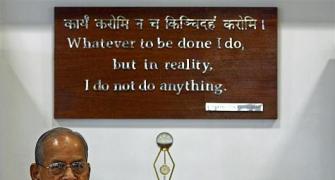

But evidence is mounting that the causes for and solutions to India’s manufacturing angst may not lie in high land costs, excessively labour-friendly laws or excessive taxes. It may lie in the sheer lack of manufacturing management expertise among our managers and business persons. This is the expertise needed to manage your factory in a way that you hold far lower inventory than your competitor, respond to an order within hours of it being received rather than in days or weeks, change over from one mix of products to another mix of products in hours, not months, and the expertise to make subtle design changes in your product and make it easier to manufacture or to repair.

A group of far-sighted people is working quietly behind the scenes to make such expertise widely available to Indian industry. The Indian Institute of Management, Calcutta, the Indian Institute of Technology, Kanpur, and the Indian Institute of Technology, Madras, have for the past five years jointly offered a one-year academic programme to train a generation of manufacturing visionaries, who will hopefully bring about a revolution in Indian manufacturing.

The course takes in executives who are already working in manufacturing companies and equips them with techniques developed in cutting-edge manufacturing companies in Japan and the United States. Techniques such as visual mapping – which helps visualise and optimise the flow of materials and information within a factory - can increase a factory’s output 50-fold or more without increasing the number of workers, or the number of hours worked, or the capital equipment deployed. These techniques do more to make a manufacturing unit competitive, compared to what cheap land or tax breaks can ever hope to achieve.

The Visionary Leaders in Manufacturing Programme, as it is called, is the result of a Herculean effort by the Confederation of Indian Industry, the National Manufacturing Competitive Council and the Japanese government. It is inspired by the legendary Japanese manufacturing guru Shoji Shiba. Faculty from IIM Calcutta, IIT Kanpur, IIT Madras and Japan join in delivering this course and in creating a community of like-minded professionals to share experiences.

The discourse on manufacturing in India has so far tended to quickly regress to one about land acquisition, tax exemptions and labour law relaxation. Business persons loudly make the claim that getting land virtually free and being exempt from state taxes are the keys to making Indian manufacturing competitive, and chief ministers of states - desperate for manufacturing jobs - oblige them by acquiring land at low prices from near-destitute peasants.

This triggers social conflict. Hopefully, a new generation of visionary manufacturing leaders, who have the skills to unravel the drivers of supply chain performance and to manage global supply chains, will elevate this discourse to one about expertise in manufacturing.

Ajit Balakrishnan is the author of The Wave Rider. He can be reached at: ajitb@rediffmail.com